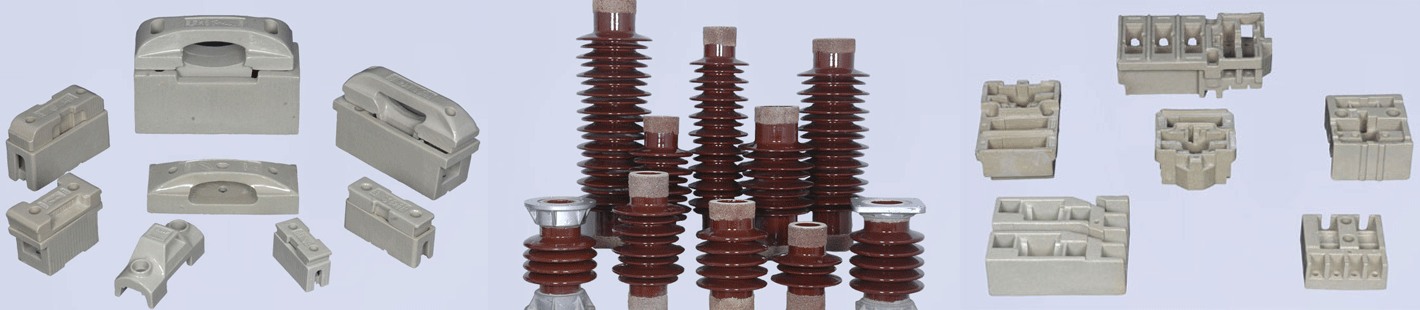

Product Range

Engineering Ceramics

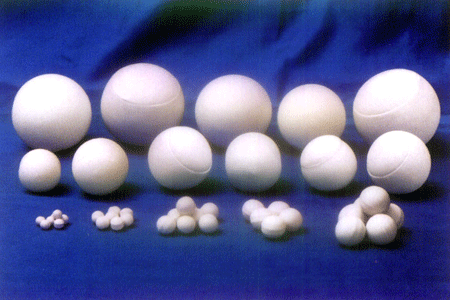

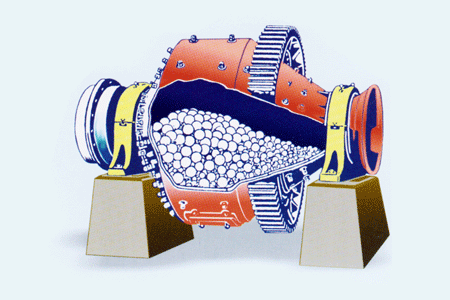

Mill Lining Bricks & Grinding Media

At RCPL, we have a range of spherical and cylindrical shaped grinding media and mill linings mainly used in the industries where milling process is required to be contamination free.

Our product is suited for a wide range of milling operation and can be used in both wet and dry applications.

The main customers are producers of ceramics tiles, sanitary ware, white cement, silica sand, ceramic glazing, ceramic inks and colors for the glass industry.

Ravituff 90 grinding media balls have high density of 3.5 gm/cc compared to conventional grinding media like porcelain, flint etc.

- Ravituff 90 - 3.5 gm/cc

- Porcelain - 2.7 gm/cc

- Flint - 2.6 gm/cc

Since grinding efficiency is roughly proportional to density of the media, Ravituff 90 Media are far more efficient than most other media commonly used, by virtue of over 30% increase in relative weight. Since weight is a very important criteria for both size reduction and solids separation, heavier the media, more work they accomplish.

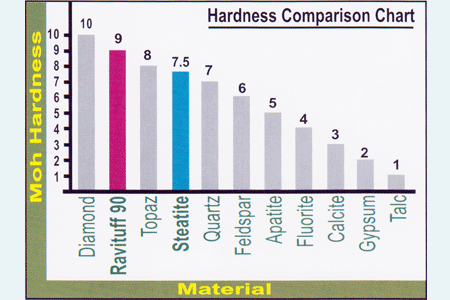

Ravituff 90 grinding media have high hardness of 9 on Moh's hardness scale, compare to conventional media material like porcelain, flint etc.

High hardness enables achieving faster grinding and finer particle distribution.

Ravituff 90 grinding media have good resistance to deformation, crack formations and its propagation (this ensures prolonged resistance to chipping and cracking). Also media replacement and make up charge level drops significantly with the use of Ravituff 90 Alumina Ceramic media. Hence Ravituff 90 media are cost effective alternative to conventional media.

Ravituff 90 grinding media are inert and non oxidizing. Hence media induced product contamination is practically nil, which leads to better quality mill output.

Ravituff 90 Alumina grinding media are best suited for a wide range of wet and dry grinding operations and can be used in industries where milling process is required to be contamination free.

The main customers are manufacturers of Ceramic Tiles, Sanitary Ware, White Cement, Ceramic Glazing, Paints, Mineral processing, etc.

Recommendations for Better Grinding Efficiency :

The recommended mill charge for efficient grinding is 50-60% of mill volume. A balanced blend of two to four media sizes is recommended for better grinding. Always cover the grinding media with at least 50 mm of the material to be grounded. Mill should operate at 60% to 70% of critical speed for optimum grinding performance. (100% critical speed=42.31/√D where D=Mill ID in Meters).